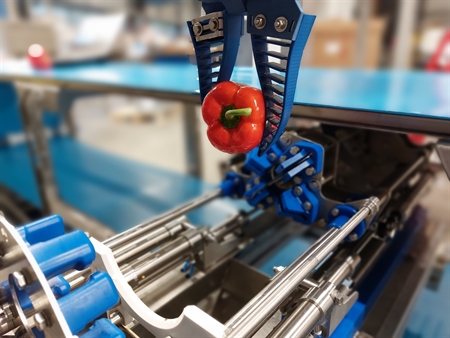

Bell Pepper Line

Designed for maximum efficiency and precision, this fully automated cutting-edge system revolutionizes the processing of bell peppers from start to finish. Picking, placing, coring, and cutting all done automated

VideoLoading Bunker: The process begins as bell peppers are deposited into our loading bunker. This automated entry point ensures a steady flow of peppers into the system without interruption.

Advanced AI vision system: As peppers travel along the transport line, they are meticulously scanned by our cutting-edge camera technology. This high-resolution camera captures detailed images of each pepper, precisely identifying their size, shape, and orientation.

Dynamic gripper control: Armed with the data from our vision system, our silicone grippers swing into action. These agile grippers, equipped with intelligent control mechanisms, precisely grasp each pepper according to its unique characteristics, ensuring gentle yet secure handling throughout the process.

Efficient coring and cutting module: Once securely held by the grippers, peppers are seamlessly transitioned into our cutting and coring module. Within this innovative module, a precision coring drill swiftly and accurately removes the pepper's core with surgical precision, guaranteeing uniformity and consistency in every pepper.

Versatile cutting options: Our system offers flexibility in cutting options to meet diverse customer needs. Whether it's halving or quartering, our cutting mechanism swiftly transforms peppers into desired segments, ready for further processing or packaging.

Streamlined operations: With seamless integration and automated workflows, our bell pepper line optimizes efficiency and reduces labor costs. Each step of the process is meticulously coordinated for maximum productivity and quality assurance.

Endless Possibilities: Whether destined for fresh produce aisles, foodservice operations, or culinary applications, our automated bell pepper line opens up endless possibilities for manufacturers and consumers alike, delivering consistently superior results with every pepper processed.

Features of the Bell Pepper Line

- Three robots and each robot with 3 processing (coring/segmenting) modules (adjustable).

- Each pepper will be processed within 2 seconds giving a maximum output of 30 x 3 x 60 = 5400 peppers per hour.

- Core will be removed from the tubes after cutting, to keep the tubes clear ready for the next pepper.

- By changing blades, the pepper can be cut in 2 halves or 4 quarters.

- An auto levelling system will ensure peppers are placed horizontally in the cutting/coring module to ensure accurate coring.

- Machine design ensures suitability for operation, maintenance, and hygiene.

Pepper specifications

Minimum length (height) 70mm

Maximum length (height) 170mm

Minimum diameter 70mm

Maximum diameter 110mm

Features of all our fruit and vegetable processing machines

• Careful treatment and processing improves the shelf life

• High processing capacity

• Maximum yield per processed product

• Equals or betters manual processing

• Attractive end product

• Easy to clean and to service

• Meets European guidelines for food-processing to hygiene and safety

Features of all ZTI smart machines

• Smart innovations that are distinguished by their simplicity

• Simple and safe to operate

• Equipped with the latest technology

• Optimum balance between ‘mechanics’ and ‘electronics’

• Attractive return on investment