Working with sharp knives requires extra safety measures

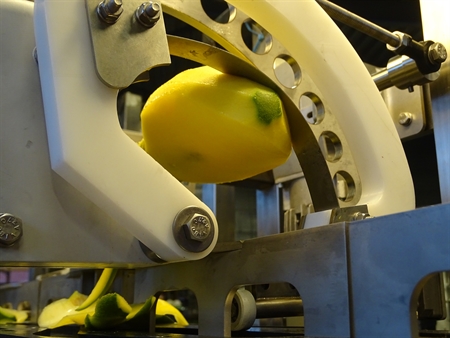

Our machines don't process fully autonomous (yet). Not that we can't make them, the costs are holding back for the time being. So an operator is needed to load the machine and who can intervene where necessary. That means human contact with the machine. It goes without saying that this must be done safely.

ZTI machines comply with European guidelines for the food processing industry with regard to hygiene and safety. This means, among other things, that an operator cannot come into contact with knives and other rotating parts while processing. Safety shields, light curtains, and sensors provide the necessary protection and shutdown or failure of the machine to start. They are part of the emergency stop circuit.

Important rules also apply to the maintenance of the machine and the replacement of wear and tear parts. For example, the mandatory wearing of cut-resistant gloves if a knife has to be replaced. Naturally, an operator is asked to read the manual carefully and to comply with the prescribed safety regulations.

All machines are equipped with one or more emergency stop button(s). When pressed during the process, the machine stops immediately. Doors that can simply be pulled open are included in the emergency stop circuit with a switch and will therefore lead to an emergency stop when a door is opened during operation. Please note, these buttons must be released manually or the machine will not startup.

Do you want to know more about the safety regulations that we use? We are happy to tell you.