How do you get the best yield result?

Of course, we all want to have yield as high as possible, or the best net result at the end of the process. Our machines can play an important role in optimizing the yield. The mechanical processing of fruit presents a number of challenges. It is important to cut away as little material as possible from fruit and to have the end product completely done of skins, seeds, and stems.

How can you increase the yield per processed product? For example by making the peeling thickness adjustable. This is made very easy with our Citrus Kiwi Peeler, the Mango Peeler-de-Cheekers and the Pineapple Peeler. This is important because the peel thickness often varies with these fruits. But the cylinders of the Pineapple Peeler can also be easily adjusted to the fruit size. In this way the machine avoids unnecessary product loss. When fruit is cut into cubes, we ensure that the cubes are more or less of the same size and that there are as few mini particles as possible. Rather making a cube a fraction too big than making waste. Sometimes this can be achieved by placing fewer knives and in other cases by developing a tray in which the product is to be cut can be unambiguously placed.

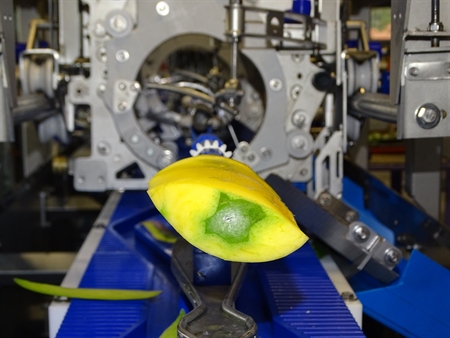

Where possible, we use thickness-adjustable peelers in our machines. These thin peelers follow the contours of the fruit without exerting too much pressure. That way you have the desired shell thickness in your own hands. In addition to the peelers, our Mango Peeler-de-Cheekers also use curved knives that remove the pit. Unique; this is something you cannot achieve with a manually peeled mango. Hand peelers always have a straight cut stone. That is therefore unfavorable for the yield.

Would you like to know more about increasing yield when processing fruit? Then ask your question here.